Welcome to SHIJIAZHUANG BO XING MACHINE CO., LTD.

Welcome to SHIJIAZHUANG BO XING MACHINE CO., LTD.

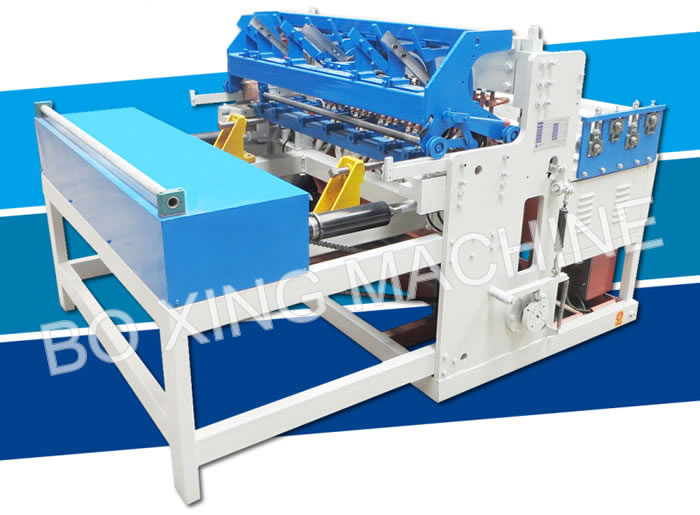

2-5mm wire mesh welding line ; (Automatic wire mesh welding production line)

Description:

The mesh welding line is especially for the production line that line wire is from spool and cross wire from pre-straightened and cut bar.

Parameter:

Welded wire mesh machine is a kind of auto welding equipment designed and manufactured by ourselves based on absorbing the advanced electromechanical controlled resistance welding technology from home and abroad, of which multinomial technologies have won the national patents.

Our welded wire mesh machine has the following major advantage:

1. Main machine frame is welded with the thicker steel panel and steel bar. The main structure is more well-set and compact.

2. The cross wire feeding hopper is originative. The cross wire feeding is automatic and driven by step motor, which makes the cross wire aligning more accurate.

3. The mesh pulling system is controlled by step motor, which makes the pulling mesh aperture more standard and accurate.

4. The mesh aperture size welded is diversified. The line wire spacing can be adjusted through the related parts. The cross wire spacing adjusting is controlled by microcomputer and it can have 10 different styles.

5. Welding adopts late-model efficient welding transformer. The voltage adjusting range is big and it can fall into eight different grades, which enlarge the range of wire diameter size.

6. In order to adapt the capacity of the clients’ main power transformer and reduce the rush of the current, electric and electronic welding control adopt the separating control electricity input, i.e., the welding transformers don’t work at the same time but in several times when welding the same row of cross wires.

Main parameters

| Model | BX-2/5-1250 |

| Mesh width | 1250mm |

| Line wire spacing | 50-100mm |

| Numbers of welding points | 30 |

| Transformer | 3*125KVA |

| Cross wire spacing | 50-200mm |

| Wire diameter | 2-5mm |

| Max welding speed | 30-40 strokes per min |

| Driving Power | 2.2KW |

| Outside transformer capacity | ≥100KVA |

| Outside cable requirement | Three 50 m2 copper wires (Equipment is distant from electric transformer≤100 m) One 20 m2 aluminum wire (used as zero line) |

| Welding way | Resistance welding controlled by Silicon-controlled rectifier (hereinafter called as SCR) |

| Welding voltage | Adjustable in eight different grades through welding transformer |

| Pressurizing way | By changing the length of tie rod in pressurizing beam and the compression of the upper electrode spring |

| Cross wire feeding way | The cross wire fall off the feeding hopper into welding automatically one by one driven by step motor |

| Wire material requirement | Coiled bar dragged annealing material shall meet the related requirements of carbon structural steel Q195F Carbon Equivalence of China GB/T701—1997, and the tensile strength shall be above or equal to 392N/mm². Surface shall be smooth and rustless, without lime removing agent, fume dirt, water stain, zinc stain (cold or hot galvanization) or altered drawing wire. |