Welcome to SHIJIAZHUANG BO XING MACHINE CO., LTD.

Welcome to SHIJIAZHUANG BO XING MACHINE CO., LTD.

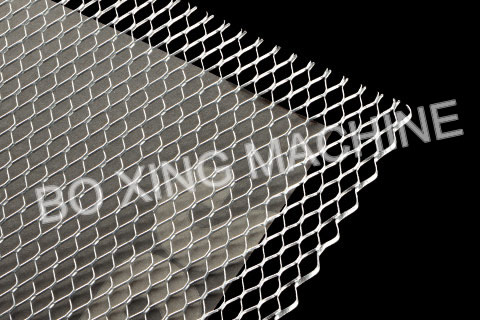

Expanded Metal lath and Brickwork mesh machine line

Self furring lath production line is used to produce the self furring lath which is applied to plaster and reinforcing the wall, the production line contains de-coiler, expanded main machine, roller profiling machine with hydraulic shearer and collecting table

Technical parameters:

The metal lath and brickwork mesh machine can produce metal lath and brickwork reinforcement mesh on one production line by change molds.

General information:

| Machine name/Brief Description | Diamond mesh machine |

| Rolling Speed | 12mpm |

| NO. of operators | Two |

| Approx. weight (Total weight) | 4 tons |

| Total power requirement | 12kw |

| Compressed air requirement (cft/min.) | 0.5M3 |

| Machine Guard | yes |

| Machine Mechanism | Rotary |

| Line direction | Left to right |

Decoiler:

| Item | Name | Parameter |

| 1 | Inner diameter | 500mm, adjustable |

| 2 | Outer diameter | 1000mm |

| 3 | Loading weight | Loading weight of each side is 1t |

| 4 | Machine size | 2650x1970x1620mm |

| 5 | Weight | 1260Kg |

| 6 | Two sides | Each rotation 180° |

Roll shearing/expanding:

| Item | Name | Parameter |

| 1 | Outer diameter of cutter | Φ263mm |

| 2 | Blade repaired capacity | 3 mm |

| 3 | Speed or roll and cutting | 12m/min |

| 4 | Motor | Power:4kw, Voltage: 380V, Rotation speed: 1450r/min |

| 5 | Machine size | 2220x1510x1810mm |

| 6 | Weight | 2352Kg |

Straightening and slitting machine:

| Item | Name | Parameter |

| 1 | Diameter of roll | 63mm |

| 2 | Straightening roller QTY | 13 straightening rollers |

| 3 | Motor | Power:3kW, Voltage:380V |

| 4 | Reduce speed machine | JZQ200—i=20.54 |

| 5 | Size of machine | 1800x1665x1725mm |

| 6 | Weight | 1554Kg |

Stacker:

| Item | Name | Parameter |

| 1 | Product size | 700x3000mm |

| 2 | Loading weight | 1t |

| 3 | Loading height | 500mm |

| 4 | Size of machine | 3610*2900*1620 |

| 5 | Weight | 586Kg |

Double head re-winder:

| Item | Name | Parameter |

| 1 | Inner diameter | 120mm |

| 2 | Outer diameter | 800mm |

| 3 | Loading weight | 300Kg |

| 4 | Motor | Power: 1.5kw, voltage: 380V, 2 sets |

| 5 | Machine size | 3240x1770x1610mm |

| 6 | Weight | 1420Kg |